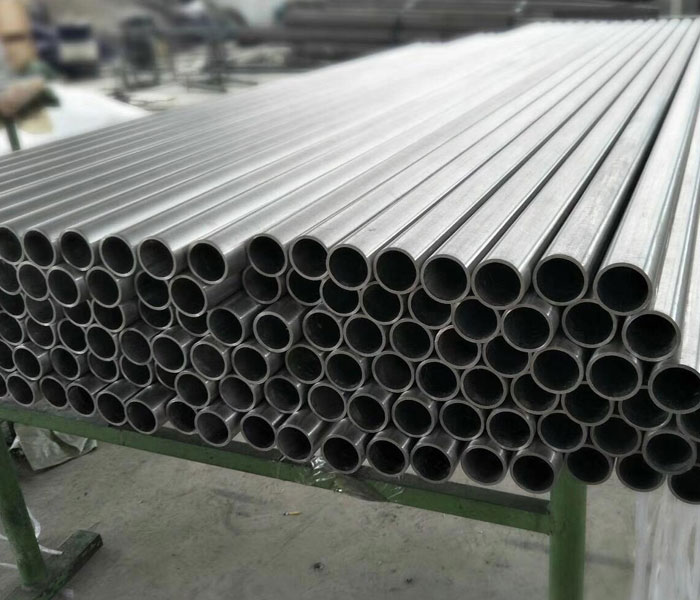

We supply a wide range of precisely engineered stainless steel pipes & tubes, made in compliance with international quality and safety standards. Our range comprises of stainless steel welded pipes & tubes. Available in different dimensions & grades, these stainless steel welded tubes and pipes are widely used in different industries like power, engineering, construction and many more. We offer products at highly competitive prices and deliver consignment within stipulated time .

Pipes Specification

| Pipes Specifications | ASTM A312, A358 / ASME SA312, SA358 |

|---|---|

| Dimensional specification | ANSI/ASME B36.19M, ANSI/ASME B36.10M |

| ASTM A312 SS Seamless Pipe Size | 1 / 2" NB - 16" NB |

| ASTM A312 SS Welded Pipe Size | 1 / 2" NB - 24" NB |

| ASTM A358 SS EFW Pipe Size | 6" NB - 24" NB |

| Outside Diameter | 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB available Ex-stock, OD Size Steel Tubes available Ex-stock |

| Pipes Manufacturing Shapes | Hydraulic, Round, Rectangle, Square, Hex, Honed |

| Pipe Manufacturing Techniques | Seamless / Welded / ERW / Fabricated / CDW / 100% X Ray Welded |

| Pipe Schedule Thickness Range | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| SS Pipes End Types | Plain End, Beveled End, Treaded One End, TBE (Treaded Both Ends) |

| Delivery Condition of SS Pipe | Annealed and Pickled, Polished, Bright Annealed, Cold Drawn |

| Surface Finish | No.1, No.4, No.8 Mirror Finish, 2B |

| Value Added Services | Cutting, Beveling, Polishing, Threading, Destructive, Non Destructive, Ultrasonic Testing |

| Inspection and Test Reports | EN 10204 3.1, Mill Test Certificates, Chemical Reports, PMI Test Reports, Mechanical Reports, Third Party Inspection, NABL Approved Lab, Visual Inspection, Destructive Test and Non Destructive Test Reports |

| Marking | Specification Grade Nominal Pipe Sizes Pipe Schedule or Wall Thickness Manufacturing Method (Seamless / Welded) Heat Number Manufacturer’s Name or Custom Logo - on request Marked Pipe Sample: ANSI B36.19 ASTM A 312 SS 12" NB SCH 40S SEAMLESS HEAT NO. XXXX |

| Outside Finish | 2B, No.4, No.1, No.8 Mirror Finish for Stainless Steel Pipes, Finish as per customer Requirements |

| Delivery Condition | Annealed and Pickled, Polished, Bright Annealed, Cold Drawn |

| Packing of Pipes | Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests |

| Specials | Sizes and Specifications other than above can be on request |

Alloy Steel Pipes & Tubes

Alloy steel pipes and tubes are crucial components in various industrial applications due to their superior mechanical properties and resistance to wear, corrosion, and high temperatures. These materials are specifically designed to offer enhanced performance compared to standard carbon steels.

| Attribute | Details |

|---|---|

| Grades Available | ASTM/ASME A335/SA335 P1, P5, P9, P11, P12, P22, P91 ASTM/ASME A213/SA213 T1, T5, T9, T11, T12, T22, T91 |

| Size Range | ½” to 24” nominal diameter |

| Thickness Range | SCH 10, SCH 20, SCH 30, SCH 40, SCH 60, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, STD, XS, XXS, and higher wall thicknesses |

| Material Specifications | ASTM/ASME A335/SA335: Designed for high-temperature service. ASTM/ASME A213/SA213: Suitable for high-temperature and high-pressure applications. |

| Grades Description | - P1, P5, P9: Used in power generation and high-temperature applications. - P11, P12, P22: Suitable for high-pressure and temperature conditions. - P91: Designed for high-temperature service with improved creep strength. - T1, T5, T9: Suitable for various high-temperature applications. - T11, T12, T22: Used in power plants and high-pressure environments. - T91: High strength and high-temperature service. |

Specification Table

| Grade | Chemical Composition | Mechanical Properties | Applications |

|---|---|---|---|

| A335 P1 | C: 0.12-0.20%, Cr: 0.30-0.60%, Mo: 0.44-0.65% | Yield Strength: 205 MPa, Tensile Strength: 415 MPa | Power generation, high-temperature service |

| A335 P5 | C: 0.05-0.15%, Cr: 4.00-4.50%, Mo: 0.45-0.65% | Yield Strength: 275 MPa, Tensile Strength: 485 MPa | Steam boilers, high-temperature applications |

| A335 P9 | C: 0.07-0.15%, Cr: 8.00-8.50%, Mo: 0.90-1.10% | Yield Strength: 415 MPa, Tensile Strength: 585 MPa | Power plants, petrochemical industry |

| A335 P11 | C: 0.10-0.15%, Cr: 1.00-1.50%, Mo: 0.44-0.65% | Yield Strength: 205 MPa, Tensile Strength: 415 MPa | High-pressure service in power plants |

| A335 P12 | C: 0.10-0.15%, Cr: 1.00-1.50%, Mo: 0.44-0.65% | Yield Strength: 205 MPa, Tensile Strength: 415 MPa | High-temperature applications |

| A335 P22 | C: 0.12-0.20%, Cr: 1.00-1.50%, Mo: 0.44-0.65% | Yield Strength: 205 MPa, Tensile Strength: 415 MPa | High-pressure service, power generation |

| A335 P91 | C: 0.07-0.12%, Cr: 8.00-9.00%, Mo: 0.85-1.05% | Yield Strength: 415 MPa, Tensile Strength: 585 MPa | High-temperature, high-strength applications |

| A213 T1 | C: 0.10-0.15%, Cr: 0.60-0.90%, Mo: 0.44-0.65% | Yield Strength: 205 MPa, Tensile Strength: 415 MPa | High-temperature service in power plants |

| A213 T5 | C: 0.05-0.15%, Cr: 4.00-4.50%, Mo: 0.45-0.65% | Yield Strength: 275 MPa, Tensile Strength: 485 MPa | Steam boilers, high-temperature applications |

| A213 T9 | C: 0.07-0.15%, Cr: 8.00-8.50%, Mo: 0.90-1.10% | Yield Strength: 415 MPa, Tensile Strength: 585 MPa | Power plants, petrochemical industry |

| A213 T11 | C: 0.10-0.15%, Cr: 1.00-1.50%, Mo: 0.44-0.65% | Yield Strength: 205 MPa, Tensile Strength: 415 MPa | High-pressure applications |

| A213 T12 | C: 0.10-0.15%, Cr: 1.00-1.50%, Mo: 0.44-0.65% | Yield Strength: 205 MPa, Tensile Strength: 415 MPa | High-temperature applications |

| A213 T22 | C: 0.12-0.20%, Cr: 1.00-1.50%, Mo: 0.44-0.65% | Yield Strength: 205 MPa, Tensile Strength: 415 MPa | High-pressure service, power generation |

| A213 T91 | C: 0.07-0.12%, Cr: 8.00-9.00%, Mo: 0.85-1.05% | Yield Strength: 415 MPa, Tensile Strength: 585 MPa | High-temperature, high-strength applications |

In summary, alloy steel pipes and tubes are vital for demanding applications where standard carbon steels may not suffice. Their ability to withstand extreme conditions while maintaining strength and durability makes them essential in many high-performance and critical systems.

Carbon steel pipes and tubes

Carbon steel pipes and tubes are widely used in various industries due to their strength, durability, and cost-effectiveness. They are primarily composed of iron and carbon, with other elements present in smaller amounts. Carbon steel is categorized based on its carbon content and properties, which determine its suitability for different applications.

| Attribute | Details |

|---|---|

| Grades Available | - API 5L: Grade B, X42, X46, X52, X56, X60, X65, X70 - ASTM A106: Grade B - ASTM A53: Grade B - ASTM A333: Grade 6 - ST52 - ST53 |

| Size Range | ½” to 42” nominal diameter |

| Thickness Range | SCH 40, SCH 60, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, STD, XS, XXS, and higher wall thicknesses |

| Material Specifications | - API 5L: Specification for Line Pipe; used for oil and gas pipelines. - ASTM A106: Standard Specification for Seamless Carbon Steel Pipe for High-Temperature Service. - ASTM A53: Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless. - ASTM A333: Standard Specification for Seamless and Welded Steel Pipe for Low-Temperature Service. - ST52: High-strength low-alloy structural steel. - ST53: Similar to ST52 but with slightly different mechanical properties. |

| Grades Description | - API 5L Grade B: Used in pipelines for moderate strength. - API 5L X42 to X70: Higher strength grades for more demanding applications. - ASTM A106 B: High-temperature applications with good weldability. - ASTM A53 B: General-purpose pipe for low- to medium-pressure applications. - ASTM A333 Grade 6: Low-temperature service with good impact resistance. - ST52: Structural steel for applications requiring high strength. - ST53: Similar to ST52, used in construction and structural applications. |

Specification Table

| Grade | Chemical Composition | Mechanical Properties | Applications |

|---|---|---|---|

| API 5L Grade B | C: 0.26-0.34%, Mn: 0.60-0.90%, P: ≤0.030%, S: ≤0.030% | Yield Strength: 240 MPa, Tensile Strength: 415 MPa | Oil and gas pipelines |

| API 5L X42 | C: 0.26-0.34%, Mn: 1.00-1.40%, P: ≤0.030%, S: ≤0.030% | Yield Strength: 290 MPa, Tensile Strength: 450 MPa | Higher strength pipelines |

| ASTM A106 B | C: 0.30-0.60%, Mn: 0.60-0.90%, P: ≤0.035%, S: ≤0.035% | Yield Strength: 240 MPa, Tensile Strength: 415 MPa | High-temperature applications |

| ASTM A53 B | C: 0.25-0.30%, Mn: 0.60-0.90%, P: ≤0.035%, S: ≤0.035% | Yield Strength: 240 MPa, Tensile Strength: 415 MPa | General-purpose piping |

| ASTM A333 Grade 6 | C: 0.30-0.60%, Mn: 0.60-0.90%, P: ≤0.035%, S: ≤0.035% | Yield Strength: 240 MPa, Tensile Strength: 415 MPa | Low-temperature applications |

| ST52 | C: 0.22-0.28%, Mn: 1.60-2.00%, P: ≤0.025%, S: ≤0.025% | Yield Strength: 355 MPa, Tensile Strength: 500 MPa | Structural applications |

| ST53 | C: 0.22-0.28%, Mn: 1.60-2.00%, P: ≤0.025%, S: ≤0.025% | Yield Strength: 355 MPa, Tensile Strength: 500 MPa | Structural and construction applications |

In summary, alloy steel pipes and tubes are vital for demanding applications where standard carbon steels may not suffice. Their ability to withstand extreme conditions while maintaining strength and durability makes them essential in many high-performance and critical systems.

Stainless & Duplex Steel

| Category | Details |

|---|---|

| Range | 15 NB up to 1200 NB in SCH 5S, 10S, 10, 20, 40S, 40, STD, 60, 80S, 80, XS, 100, 120, 140, 160, XXS |

| Form | Seamless / ERW / Welded in Round & Square |

| Stainless Steel | ASTM/ASME SA 312 GR. TP: 202, 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316TI, 316H, 316 LN, 317, 317L, 321, 321H, 347, 347H, 904L ASTM/ASME SA 358 CL 1 & CL 3 GR: 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316H, 321, 321H, 347 |

| Duplex Steel | ASTM/ASME SA 790 UNS NO: S31803, S32205, S32550, S32750, S32760 |

Nickel Alloy

| Category | Details |

|---|---|

| Range | 15 NB up to 1200 NB in SCH 5S, 10S, 10, 20, 40S, 40, STD, 60, 80S, 80, XS, 100, 120, 140, 160, XXS |

| Form | Seamless / ERW / Welded in Round & Square |

| Nickel Alloy | ASTM/ASME SB 163 UNS 2200 (Nickel 200) ASTM/ASME SB 163 UNS 2201 (Nickel 201) ASTM/ASME SB 163/165 UNS 4400 (Monel 400) ASTM/ASME SB 464 UNS 8020 (Alloy 20 / 20 CB 3) ASTM/ASME SB 704/705 UNS 8825 (Inconel 825) ASTM/ASME SB 167/517 UNS 6600 (Inconel 600) ASTM/ASME SB 167 UNS 6601 (Inconel 601) ASTM/ASME SB 704/705 UNS 6625 (Inconel 625) ASTM/ASME SB 619/622/626 UNS 10276 (Hastelloy C 276) |

Hastelloy

| Category | Details |

|---|---|

| Size | 1/2" NB to 12" NB |

| Grade | Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000 |

| Standard | Hastelloy Seamless Pipe Hastelloy ERW Pipe |

| Application | Petrochemicals Plants Oil Refineries Fertilizers Plants Sugar Mills Chemical Plants Pharmaceuticals Textile Machinery |

| Types | Seamless / ERW / Welded / Fabricated |

Inconel

| Category | Details |

|---|---|

| Range | 15 NB up to 600 NB in SCH 5S, 10S, 10, 20, 40S, 40, STD, 60, 80S, 80, XS, 100, 120, 140, 160 & XXS |

| Grade | Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 |

| Length | Single Random, Double Random & Cut Length |

| Types | Seamless / ERW / Welded / Fabricated |

| Form | Round, Square, Rectangular, Hydraulic, etc. |

| End | Plain End, Beveled End, Threaded |

Incoloy

| Category | Details |

|---|---|

| Grade | Incoloy 800, Incoloy 825, Incoloy 925, Incoloy A-286, Incoloy DS |

| Standard | ASTM B407, ASTM B829, ASTM B514, ASTM B775, ASTM B515, ASTM B751 |

| Types | Seamless / ERW / Welded / Fabricated |

| Application | Petrochemicals Plants Oil Refineries Fertilizers Plants Sugar Mills Chemical Plants Pharmaceuticals Textile Machinery |

Monel

| Category | Details |

|---|---|

| Size | 1/2" NB to 12" NB |

| Form | Round, Square, Rectangular, Hydraulic, etc. |

| Grade | Monel 400 |

| Types | Seamless / ERW / Welded / Fabricated |

| Length | Single Random, Double Random & Cut Length |

| End | Plain End, Beveled End, Threaded |

Titanium

| Category | Details |

|---|---|

| Type | Seamless / ERW / Welded / Fabricated |

| Grade | Grade 1, Grade 2, Grade 3, Grade 4, Grade 5, Grade 7, Grade 9, Grade 23 |

| Range | 15 NB up to 600 NB in SCH 5S, 10S, 10, 20, 40S, 40, STD, 60, 80S, 80, XS, 100, 120, 140, 160, etc. |

| Form | Round, Square, Rectangular, Hydraulic, etc. |

| Length | Single Random, Double Random & Cut Length |

| End | Plain End, Beveled End, Threaded |